Automatic Feature Detection: Using the Features - Tab & Options

Time to read: ~4 min

The Features Tab is used to perform detection and conversion of geometric shapes. This is applicable to bodies that originate

from applications where they were generated based on clearly defined parameters or similar. If the data originates from 3D scans

it may be possible to use these tools too, but due to noise being introduced, chances are that the features are not going to be

accurately detected.

If the source of the data is from a modeling tool (or scanner) that defines highly organic shapes (i.e. not geometric such as

faces, animals or similar) then it is likely that the tool will not find any reasonable amount of geometry to replace the data

with - as there is none...

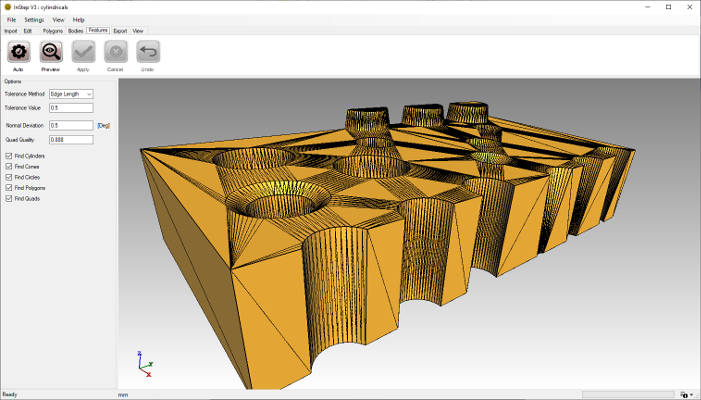

The image below shows a typical use scenario where some block has been defined with different cylindrical and planar features

such as cylinders, holes, cones, etc. With such data, the application can reverse-generate the underlying geometries and

replace the data, making it far more compact:

Facetted Body defining cylindrical, conical and planar shapes

Facetted Body defining cylindrical, conical and planar shapes

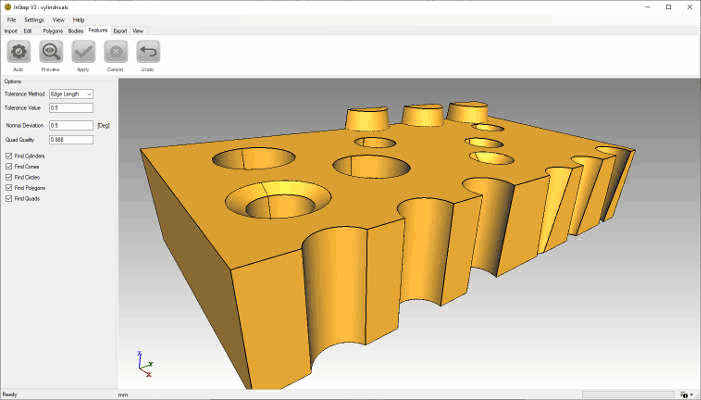

By performing an automatic detection and conversion of the data, the original facets are replaced with a geometry-based definition:

Feature based BRep model

Feature based BRep model

Here all surfaces - whether cylindrical, conical, circular or of flat polygonal shape - are redefined which reduces the original

number of facets from 4,586 down to 70.

The following items explain the tools available on this tab-page:

Auto

Auto

The Auto button performs automatic detection and conversion of all features selected in the Options below:

- Tolerance Method

- Some of the detections require that a tolerance is provided by which 'close' items can be detected. Possible values are

Edge Length, Absolute or Body Size.

Edge length (Default) uses a factor (Tolerance Value) of the local-minimum edge length as the tolerance value.

Absolute directly defines the tolerance value.

Body Size obtains the tolerance as a factor of the total size of the body.

- Normal Deviation

- This sets the amount of tolerance to allow between facets that are to be considered parallel.

- Quad Quality

- This value refers to a Quality Metric calculated for Quadrilateral elements. If they have a value below this, they are not considered. This is intended to allow only items

that are close to a square/rectangle to be considered as such rather than items that are otherwise better left as triangles.

- Find 'X' Checkboxes

- Each type of shape can be optionally ignored if the process either is unlikely to find them or is not performing well.

Preview

Preview

The Preview button performs the detection of features but does not perform the conversion (see Apply below). Items that belong to or are

identified as certain geometric features are then grouped and displayed with the option to show/hide different types. This allows validation

that process is correctly identifying the shapes contained in the data.

Apply

Apply

If the detection correctly identified the features of interest, clicking Apply then performs the conversion of the underlying triangles to

the respective geometric feature identified. As with all processes, if there is a very large amount of data, it may take some time to complete.

Cancel

Cancel

If the detection of features does not complete as intended, the data can be removed/cleared by clicking the Cancel button. This clears

the associations that identify groups of triangles as features and the process can be repeated after changing parameter options to perhaps

better identify the shapes.

Undo

Undo

If the Settings are enabling data storage for an Undo operation and Feature conversion

has taken place, it is possible to revert the data to the previous state.

It should be mentioned that, especially for very large bodies, the process of generating and storing undo data can be very time and resource

consuming and disabling the Undo option may be preferred in those cases.